iGRiP is a Canadian company, specialized in the design and manufacturing of screw studs since 2015, with over 10 years’ experience in the field. Our studs, innovative, with a unique design and superior quality, are suitable for any kind of vehicle and will meet your needs.

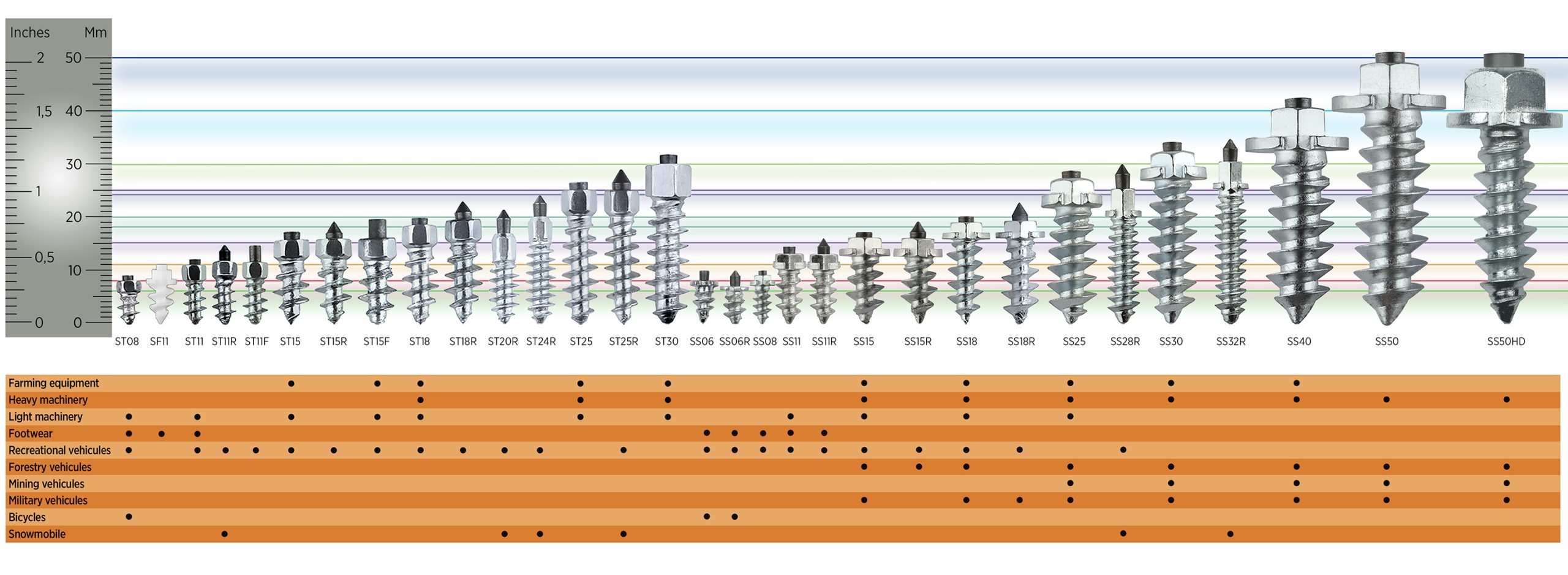

The reputation of our products is renowned, because of their safety, their simple installation and our comprehensive range of long-lasting solutions suitable for any weather condition. We have several kinds of studs designed for automobiles, agricultural vehicles, heavy and light machinery, recreational vehicles, snowmobiles, forest vehicles, military vehicles, mining vehicles and bikes, as well as for safety boots.

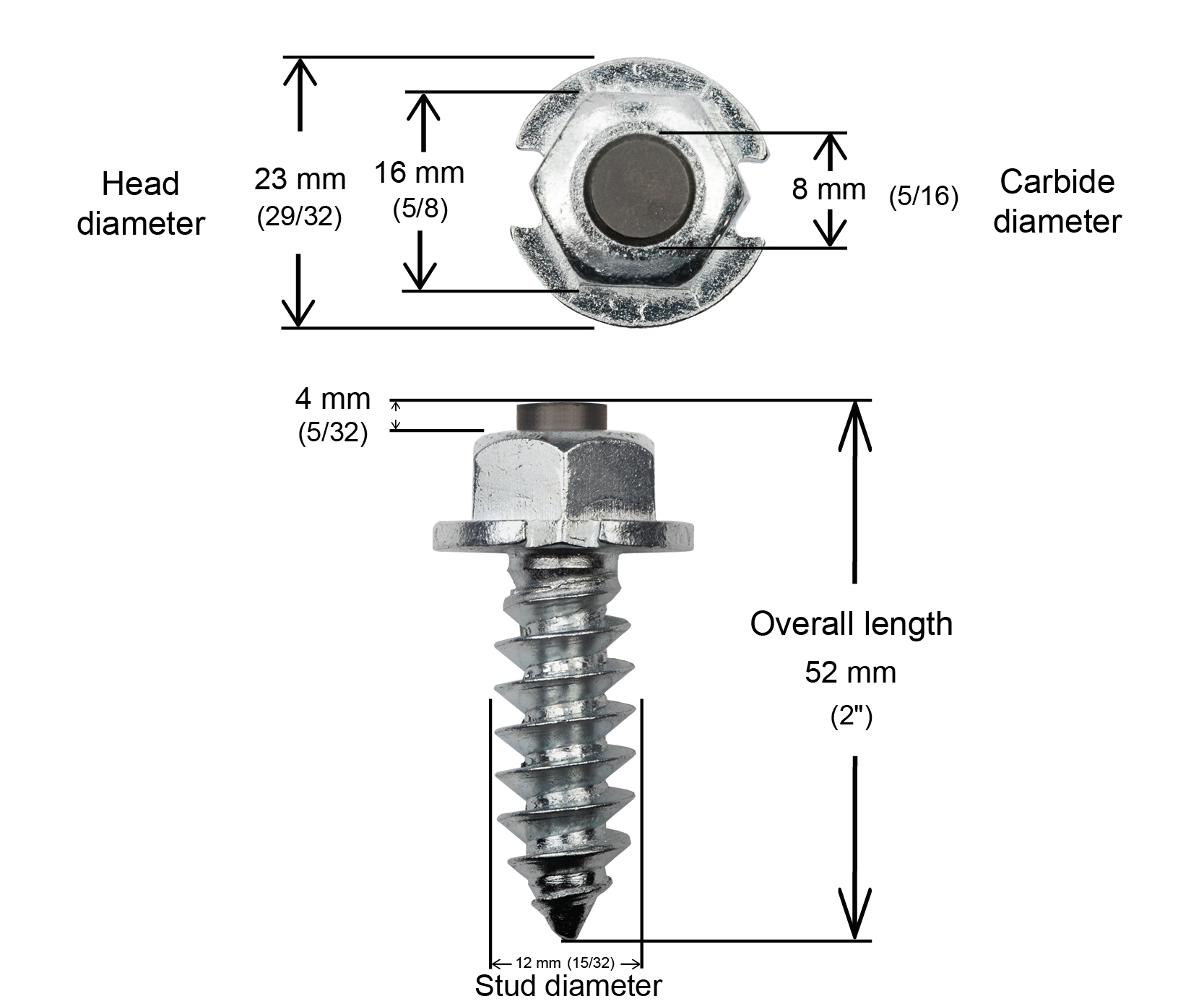

All iGRiP studs are manufactured in hot dipped steel to maximize their durability and with a zinc heat galvanization process which acts as a shield against corrosion. All studs are equipped with a tungsten carbide point to provide a continued and increased traction. This is possible thanks to unparallelled depth of the stud’s anchoring in the ice. Easy and quick to install, especially because of the tool provided, the iGRiP stud may be used without any difficulties more than one season on new or used tires. As well, the studs are easy to remove, as needed.

For many years iGRiP has offered ST-type (standard thread) studs. However, in order to improve the product range, iGRiP has added two stud types to the stock, thus answering to the customers’ needs.

The SS (shoulder studs) models were designed for heavy machinery and all kinds of vehicles used in extreme conditions and environments. As well, there are SF (spark free) model studs, which, as the name suggests, do not create sparks when in contact with the ground.

ENHANCED SAFETY

Footwear, tires and tracks will immediately have an increased level of safety after the installation of iGRiP studs, which allows better control of the vehicle when used in slippery terrains.

SUITED TO YOUR REALITY

It is possible to choose and vary the number of studs inserted in the tire or in the footwear soles in order to respond to specific needs.

Moreover, the variable depths and lengths guarantee an optimal grip of the tires, tracks or boot soles on ice, snow, mud, slippery rocks or frozen roadways. For control, effectiveness and safety, choose among our wide selection of versatile screw studs.

3 stud models :

ST – Standard Thread stud

SS- Shoulder Stud

SF- Spark Free stud

Here is a video of a Bobcat with iGRiP studs

For heavy machinery equipped with tracks, we recommend using the shoulder studs (SS). Always ensure that the shoulder of the stud is embedded in the rubber.

You can watch installation video on our youtube channel https://www.youtube.com/@igripstud

The first thing to do before choosing a stud is to take the height of the track lug. The deeper the penetration of the stud, the better!

Since these machines tend to go from left to right, you better use enough studs. When there are enough studs, the weight is well distributed between each of them and this causes less stress on them.

For this machine, we usually use the SS-30 or SS-25. We install 150 to 200 studs per track.

For this video, the guy didn’t install enough studs, only 100 per tracks. He is very happy but he should have installed more. We must not forget that this customer does not take off the studs and keeps them on all year round, it even helps on rock and dirt.

For snow groomers tracks, we use the SS-50, we usually use about 1000 studs per machine. The SS-40 / SS-50 / SS-50HD must be pre-drilled and it always comes with glue.